Quality Control

We firmly believe that true premium quality can only be achieved through the perfect advanced machines and the finest materials.

When it comes to our paper cups, each material used is meticulously handpicked by our team of raw materials experts to guarantee not only top-quality but also a commitment to environmental sustainability.

Our Process

-

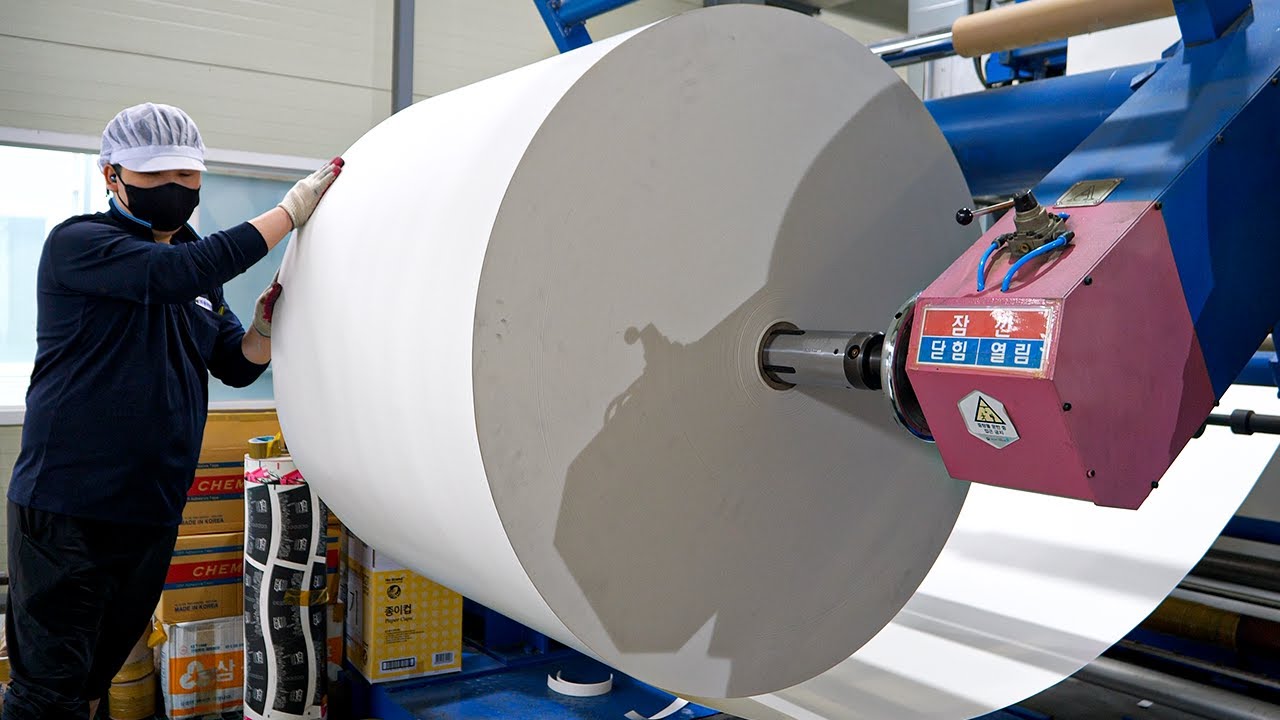

Coating

Water-based barrier & Cup Stock applied to the surface of a paper cup to make it resistant to liquid penetration and leakage.

-

Printing

The desired graphics, logos, or designs are created using graphic design software or by working with a professional graphic designer, MAX 4 colors.

-

Cutting

The paper material is precisely cutting and shaped into individual cup blanks or templates

-

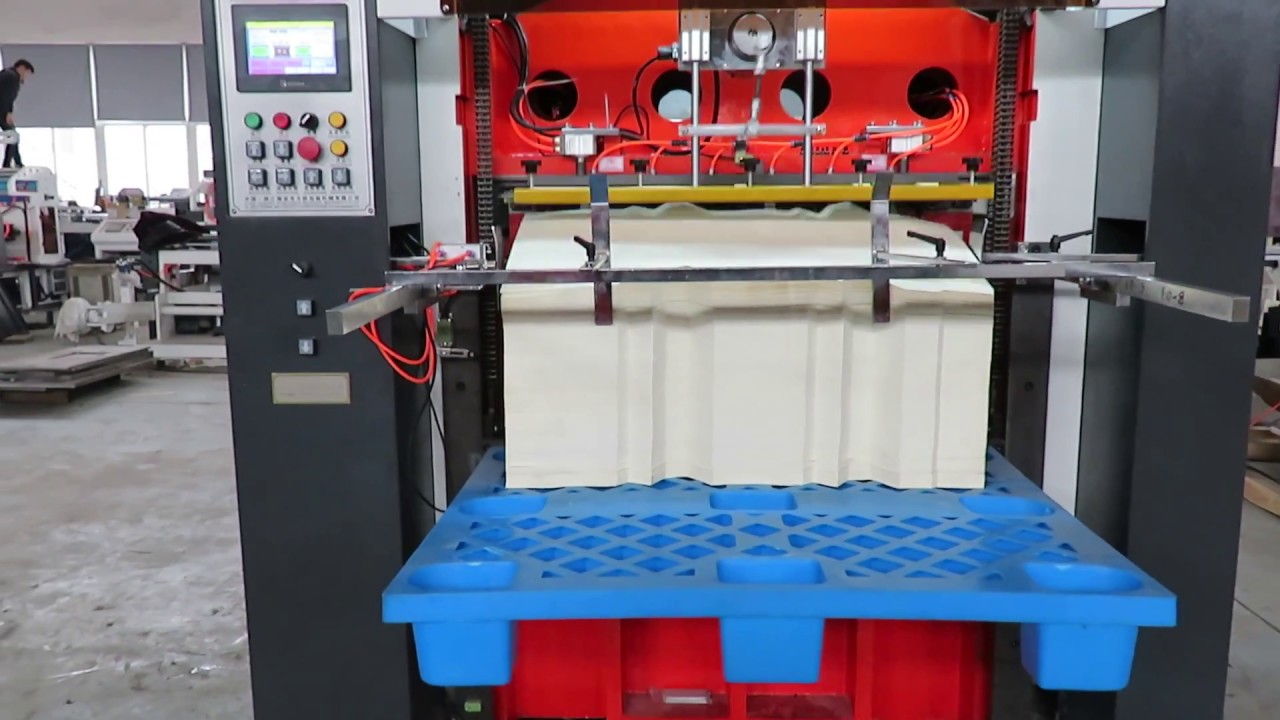

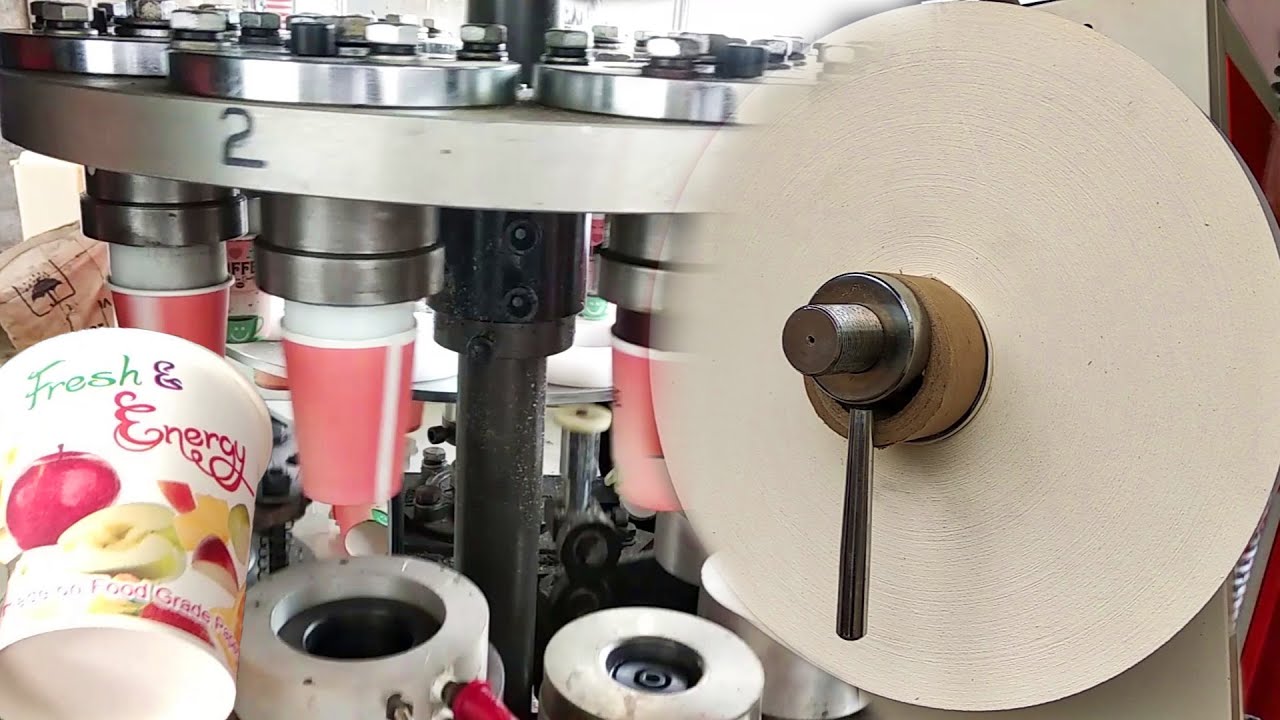

Shaping

The cup blanks are fed into a cup forming machine, which uses heat and pressure to sealing the cup blanks into a cylindrical form, speed 120 pieces/min

-

Testing

Cups are measured to ensure they meet the specified dimensions and capacity. checking the height, diameter, and volume of the cups, test within 18 hours

-

Packing

The carton packs facilitate the handling and transportation of paper cups. Sturdy and durable structural support to prevent from shifting or getting crushed during transit.